In the field of advanced material science and pharmaceutical development, the ability to remove moisture and solvents without compromising the chemical integrity of a sample is vital. Standard convection heating often falls short when dealing with delicate substances that are prone to oxidation or thermal degradation at high temperatures. This has led to the widespread adoption of specialized drying technology that operates under reduced pressure. By lowering the boiling point of liquids, these systems allow for rapid drying at much lower temperatures than conventional methods.

The thermal distribution within a low-pressure chamber is fundamentally different from a standard air-circulating unit, requiring high-precision engineering to ensure uniformity. Industrial researchers rely on these units to create high-purity samples for testing in sectors ranging from aerospace to food technology. A high-performance vacuum oven provides a controlled environment where oxygen levels are minimized, preventing unwanted chemical reactions during the drying cycle. Selecting the right equipment is essential for maintaining the accuracy of laboratory results and the safety of the researchers involved.

The Essential Role of Vacuum Technology in Modern Laboratories

The primary advantage of using a vacuum oven is its ability to dry materials that are highly porous or have complex geometries that trap liquids. By removing the air from the chamber, the system creates a pressure differential that pulls moisture out of the deepest parts of a sample. This is particularly important in the production of electronic components where even a trace amount of moisture can cause a circuit failure. The lack of air also reduces the risk of dust contamination, which is a critical factor in cleanroom environments.

Enhancing Precision in Moisture-Sensitive Research

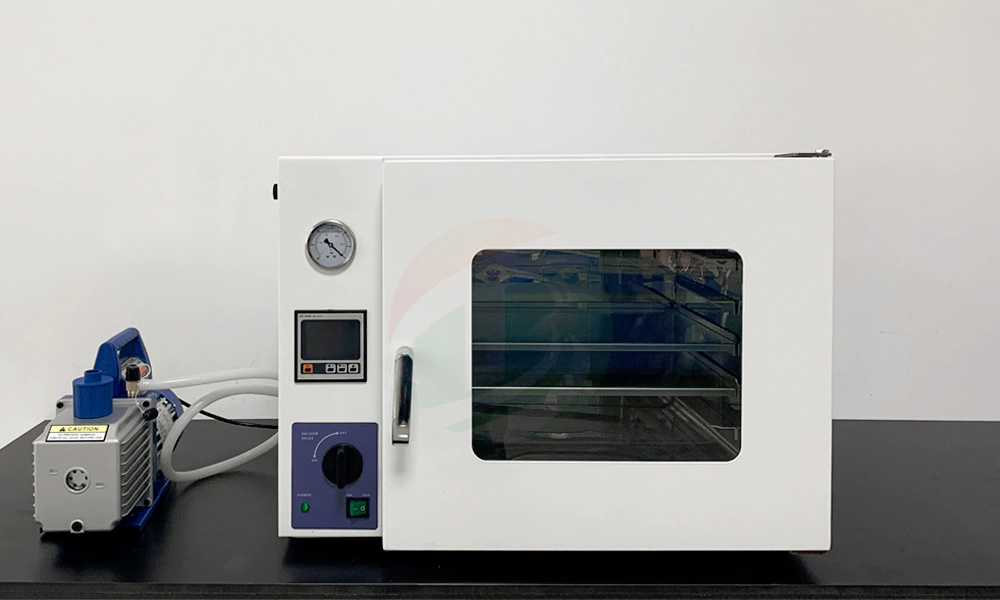

For scientists working with volatile organic compounds, a laboratory vacuum oven offers a much safer way to manage solvent evaporation. Because the boiling points are lowered, the energy required to vaporize the liquid is reduced, making the entire process more energy-efficient. These ovens are equipped with heavy-duty glass doors and specialized gaskets that can maintain a perfect seal even under high vacuum levels. This level of environmental control ensures that the researcher can repeat experiments with high consistency and minimal variables.

Mechanical Integrity and Thermal Distribution in Oven Design

The construction of a vacuum oven must be robust enough to withstand the atmospheric pressure acting on the outside of the chamber when it is evacuated. Manufacturers use high-grade stainless steel and reinforced walls to prevent any structural deformation during operation. Radiant heating elements are typically used to transfer heat directly to the shelves, ensuring that the samples receive consistent thermal energy. This design prevents “hot spots” that could lead to the uneven drying or scorching of sensitive materials.

Applications Across Pharmaceuticals and Materials Science

In the pharmaceutical sector, a laboratory vacuum oven is indispensable for the production of heat-sensitive active ingredients and dry powder inhalers. It allows for the removal of residual solvents from crystalline structures without affecting the potency of the drug. Similarly, in materials science, it is used for the “degassing” of epoxies and polymers to prevent bubbles from forming in the final molded product. The versatility of vacuum-based drying makes it a cornerstone of modern industrial R&D across multiple disciplines.

Selecting the Right Equipment for Long-Term Laboratory Success

When choosing a vacuum oven for a research facility, it is important to consider the pump capacity and the temperature range required for your specific applications. A high-quality unit should feature an intuitive digital controller that allows for precise programming of heating ramps and soak times. Ensuring that the oven is compatible with the chemicals being used in the laboratory prevents the premature corrosion of the internal chamber. Investing in a well-engineered unit provides a reliable and safe tool for years of scientific discovery.

Vacuum ovens have become an essential tool in industrial research, setting a high standard for precision, efficiency, and controlled drying. As reliable equipment widely used across laboratories, a vacuum oven offers the ability to process heat-sensitive materials without the risk of oxidation or contamination.

The proven performance and consistent results of a laboratory vacuum oven make it a dependable choice for researchers seeking accuracy and repeatability in advanced industrial and scientific applications.