Modern manufacturing hinges on precision machine engineering. Many industrial businesses seek such services for their technical manufacturing units. As it is a highly specialized domain, it is necessary to choose an expert agency.

In Canada, there are firms like Locus Precision that specialize in the niche domain of precision metal machining. They provide end-to-end services to execute complex projects.

This article takes you through the nuances around precision engineering firms and how to select the right agency for your needs.

Let us begin!

What is precision machining?

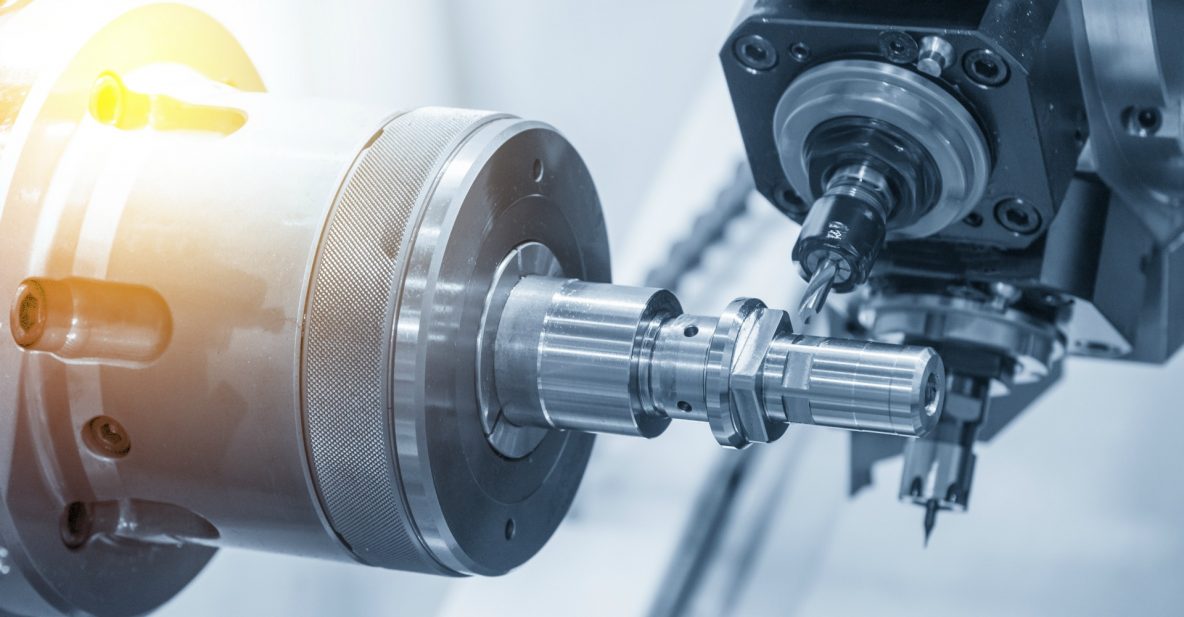

Precision machining is a type of technical manufacturing that involves the creation and design of machines, tools, and other hardware associated with modern manufacturing. It operates under extremely rigid specifications.

Some common applications are

- Subtractive precision machining: Material needs to be removed from a raw product to create the finished product.

- High precision tolerance: Manufacture of components that need to function under very tight tolerance margins and exhibit high durability.

- Repair of components: Precision machining is used to undertake machine calibration, grooving, or welding to restore a worn component to its original state.

How does precision machining work?

- Custom software like computer-aided design(CAD) and computer-aided manufacturing(CAM) is used to create the design.

- Raw materials such as plastic, metal, or ceramic are utilized to create fine-featured products using engineered tools.

- Software like CAD is programmed to meet high tolerance levels as desired by the client.

- The tools used frequently include milling machines, lathes, EDMs, saws, grinders, etc.

- The manufacturing equipment is controlled by a computer to remove the substrate material to create finer components as required.

- Some cases require the use of high-speed robotics and photochemical processes to achieve the final finely-detailed product.

How to select a precision machining firm?

Choosing the right precision machining firm is crucial to achieving optimal production gains.

Some criteria are:

- The firm should provide prototypes and small runs in short delays as per the client’s demands. This can speed up the design validation process.

- The firm should provide post-operation support in the form of turn-key services.

- The firm should offer rush order services to deliver products in a short time frame.

- The firm should offer reverse-engineering and refurbishing of metal components as well.

Concluding thoughts

The demand for precision machining has improved in recent times due to the boom in technical manufacturing. The industrial business houses should choose an experienced agency to tap the potential of the sector.