An in good repair fuel nozzle allows the turbine to operate properly, be clean, and be reliable. When the nozzle gets to the point of operating incorrectly, the first indicators are almost always unnoticeable slight changes in starts, emissions, or temperature spread.

If you can identify these indicators early, you can reduce the risks of forced outages and damage to the hot section of the turbine. These practices are consistent with good industrial gas turbine services practices and good reliability-centered maintenance (RCM) programs. To know more about this, follow this link https://www.wbdg.org/resources/reliability-centered-maintenance-rcm.

How to Spot Early Nozzle Issues

The first indicators of a potential issue usually come from small changes in performance before they lead to a fault or trip. The indicators will generally be consistent with each other over several starts or at steady load levels, and not just a one-off anomaly. It is helpful to keep a simple logbook to record (and monitor) any potential indicators, making it easier to identify patterns during each routine round and borescope inspection.

- Longer light-off times or higher fuel flow on start-up than normal

- Increasing exhaust temperature spread between thermocouples at same load

- Unstable combustion (low frequency rumble), not previously present

- CO/NOx is increasing but the operating conditions have not changed

At each combustion inspection (CI), you will use these indicators to confirm (compare against the previous baselines), that there is indeed a real trend.

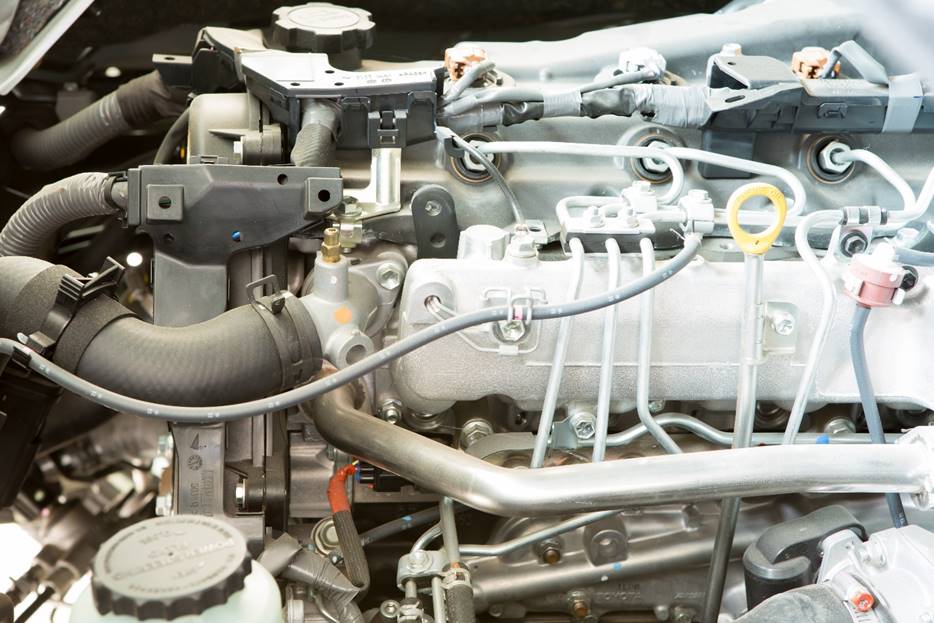

Why Poor Atomization Leads to Problems

A fuel nozzle must deliver a fine, even spray of fuel. After some time, the orifices are eroded, or coke build-up can become severe enough that the droplets become larger and the conical spray pattern becomes less even. The poor atomization can lead to incomplete mixing, hot streaks, and deposits in the combustor that can accelerate wear in downstream parts. You can perform a quick spray pattern calibration during a scheduled service to verify the cone angle and pattern distribution are still within specification (range).

If not, do not attempt to tune around the problem but rather schedule a timely fuel nozzle repair. It will help you save on fuel, deal with less emissions headaches and keep flame stability where it belongs.

What Happens If You Ignore Fuel Nozzle Wear?

When you run with a worn or dirty nozzle your unit rarely fails fast, it will instead fail slowly, and expensively. As your pattern comes apart, the thermal gradients become larger causing downstream components to wear prematurely. Chances are you can limp along for a while, but the repair dollar continues to stack up every hour you fire.

- Increased metal temperatures and higher localized hot spots, that reduce the life of parts

- Disturbances from frequent starts, and trips due to lean blowout or unsteady flame at low loads

- Increased slagging and deposits that elevate maintenance time and risk

- More frequent tuning interventions, especially on DLN combustor tuned units

If left unaddressed, the minor maldistribution has turned into a hot section repair sooner than planned.

Routine Inspection Steps for Operators

As the operator you need to use scheduled time to build in nozzle checks to your normal shift rhythm. Start with the data you already collect, starting fuel flow, ignition times, spread on exhaust temperature against a near baseline. Review emissions with the same settings for load and ambient conditions; creeping CO is a frequent indicator. If hazarding a guess is permitted, if you can get to it check the fuel filter differential pressure, contamination and or water above the smart keys.

After shutdown check for leaks on drains and manifolds, if you notice trends of imbalance manage with your service provider to schedule flow bench testing, and document every finding in the CMMS (see more here) so you can start to connect patterns over weeks and not days. If your site is using system condition-based monitoring (CBM), enable alarms on critical notifications for start fuel flow, and exhaust spread to help flag issues early.

Extending the Life of Combustion Parts

Controlling what is introduced to the combustor (combustion system) and how it is operated, extends the life of the nozzle and liner. Fuel cleanliness, warm-up discipline, and purge practices consistently all contribute. Consider it cheap insurance on expensive hardware, and anything system changes should be thought through in consultation with your controls team and maintenance vendor.

- Ensure your fuel cleanliness standards are strictly adhered to, and prompt action taken on water or particulate alarms

- Follow all recommended ramp rates, purge times, or cooldown procedures to reduce thermal shock

- Maintain up-to-date staging and load transfer settings outlined in your units operating reality; stop the temporary fixes

- Schedule periods of combustion liner refurbishment to ensure nozzles upstream do not introduce premature wear downstream

With a committed focus on trends—and prompt action when patterns deviate—you can help ensure that small nozzle issues do not escalate to large outages. You will see the payer off period…lower emissions, more stable operation and longer intervals before significant overhauls.